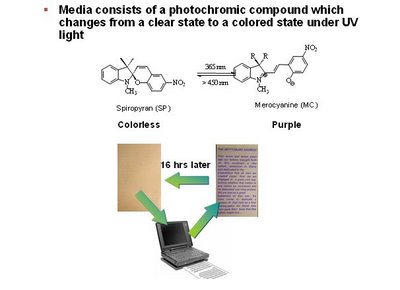

Graphic showing the "invisible ink" effect of the Xerox "photochromatic compound" transient document process. Image Credit: Xerox Corp.

Graphic showing the "invisible ink" effect of the Xerox "photochromatic compound" transient document process. Image Credit: Xerox Corp.At Xerox, It's Here Today ... Gone Tomorrow! - Originally posted 9/8/06

Just when you begin to think that paper documents are about to be a thing of the past ... "Everything is going digital!" ... Xerox reveals that it still is applying R&D assets on hardcopy processes.

That's right, there is an identified need to have a printed (on a sheet of paper) document that has a ticking-time value for its intended use. The image is applied to the paper, then, after about sixteen hours, the image disappears.

We at Symblogogy will define the document derived from this process as a "Workday Lifetime Document" or WLD.

Output from a Xerox inkless printer. Images last only about one working day. Image Credit: Xerox via TFOT

Output from a Xerox inkless printer. Images last only about one working day. Image Credit: Xerox via TFOTExcerpts from PC Pro (United Kingdom) -

Xerox reveals transient documents

By Alun Williams – PC Pro - Thursday 7th September 2006, 11:04 AM

Xerox has lifted the veil from some of its research and development work in the field of printing. The cutting-edge research highlighted at a press event involved current projects that are expected to see the commercial light of day within 18-months, including a twist on the theme of invisible ink.

Mario Jarmasz, an engineer from one of the company's R&D centres, in Grenoble, was speaking at the launch of the Xerox's entry-level A4-only multi-function printers. As well as a looking at 'print infrastructure mining', which brings the techniques of data mining to enterprise print logs to better optimise the flow of print jobs around an organisation, he also demoed the very intriguing 'transient documents'.

This offers the prospect of reusable paper in the sense that the content is automatically erased after a period of time, ready for fresh printing. Inspired by the fact that many print outs have a life-span of a few hours (think of the emails you may print out just to read, or the content you proof read on the train journey back home), the specially prepared paper will preserve its content for up to 16 hours.

XRCC researcher Peter Kazmaier with erasable paper output in the lab. Image Credit: Xerox via TFOT

XRCC researcher Peter Kazmaier with erasable paper output in the lab. Image Credit: Xerox via TFOTThe paper has a photochromic compound that changes from a clear state to a coloured state under ultra-violet light. This can create the print face, which will duly fade with time. Further research is being undertaken to give the option of subsequently preserving the content if the user desires, which might literally involve warming up old data through the heating of the paper.

----

Jarmasz also demonstrated the company's work on mobile document imaging, for example capturing data from business cards through a process of OCR compression and then transmission. Possible developments of this work include expanding email interfaces to incorporate handwritten input and the management of distributed forms.

Xerox, of course, is legendary for its Palo Alto Research Center (PARC), which claims credit for developing Ethernet and laser printers as well as the first personal computer. Having developed the machines, the researchers then wanted to connect them and then to print, and the rest is history.

Reference Here>>

Okay ... so, what do you think about this technological document imaging "breakthrough"? Symblogogy would like to hear your thoughts. The lines are open!

UPDATE - This, from interview posted at The Future Of Things 2-15-2007 -

To learn more about Xerox's inkless printer technology, an interview with Dr. Paul Smith, laboratory manager at the Xerox Research Centre of Canada, provides updated insights.

Q: When did you start working on the erasable paper technology and what was the motivation for the project?

A: We began work on erasable paper about three years ago. This followed extensive research by our work practices team from PARC who spent time with customers in offices. People still like the feel and look of paper—it is one of the best ways to communicate and show information. But our customers told us they would like to use a little less paper, so we began working on ways to create paper documents that could be reused.

Q: Did you have a Eureka! moment during the development?

A: The Eureka moment really came during the discussions with customers when we determined that two of every five documents are only used for as little as a day or even for less than a minute. Individuals might print their calendar or memos for a meeting or even the header sheet that goes with networked printers that tells who the document belongs to. You use that literally for only a minute and then put it in the recycle box.

Q: How does the erasable paper work? Could it be used to print in color?

Dr. Paul Smith with inkless output from two different runs. Image Credit: TFOT

Dr. Paul Smith with inkless output from two different runs. Image Credit: TFOTA: The erasable paper is not really printed. The paper is coated with a coating of only a few microns. This overlay contains chemicals that are activated by a light bar in the printer or multifunction device that creates the image. At this time the image is black or a dark purple color. It is conceivable that color could be created, but we are not working in that area now.

Although on the surface it may appear simple to develop a paper that can be imaged using UV light alone and then fades at a specified rate at room temperature, in practice there are many complex elements which must come together to make this a viable technology. Erasable paper technology is based on a photochromic concept similar to transition sunglasses which turn dark in bright sunlight and are seen through in a dark room. In the case of sunglasses the photochromic molecule, normally from a class of molecules such as spiropyran, reversibly converts from a colorless form to a colored form. In the case of the erasable paper, the compound that is present within the paper also turns from a colorless form to colored when exposed to a specific wavelength of light. The compound then gradually reverts back to its original colorless form over a period of time.

The end result is a reusable paper which feels very much like regular paper and is not at all like the older, waxy fax paper. The reusable paper technology has been developed from scratch but does incorporate elements which have been disclosed before. With respect to the light source, it is just beyond the blue end of the visible light spectrum. The intensity required is directly related to the writing speed that one would like to support.

Q: Can we describe what you have developed as an inkless printer?

A: People normally associate printing with inks and toners which are deposited onto the paper to make the image. This in fact is an inkless printer. The media itself creates the image after exposure to light.

Q: How many write-rewrite cycles did you perform with each paper?

A: We have been able to rewrite on the paper as many as fifty times.

Q: What printing resolution did you achieve?

A: We currently use 150 dpi, but this is not a limitation, this is just due to the resolution of the image bar that we use. This resolution is more than adequate considering the documents that are being considered for use with transient documents such as cover sheets and e-mails. We could have a much higher resolution if required.

Q: Since the paper is sensitive to U.V. radiation, what happens if you leave paper near the window or even outside on a sunny day?

A: This paper responds to a specific wavelength of light and requires a certain intensity level to change color. The intensity required is higher than the intensity observed in sunlight.

Q: Many other technologies developed in the past by Xerox failed to materialize and were later introduced by other companies. Do you fear a similar fate for the erasable paper?

Xerox's erasable paper—gradual disappearance over time. Image Credit: Xerox via TFOT

Xerox's erasable paper—gradual disappearance over time. Image Credit: Xerox via TFOTA: It is sort of a Silicon Valley myth that Xerox has not been successful in bringing technology products to market, yet we are a $15.7 billion company based on technology that we created ourselves. Our researchers invented the Ethernet, the first laser printer, the first plain-paper fax machine and the graphic user interface. There have been more than 40 successful spin-outs and startups based on Xerox technology. We are confident, based on our extensive focus groups, that there is customer interest in this project and that we will be able to develop a successful product.

Q: Can the erasable paper be used for security purposes?

A: There are many potential applications and a large amount of interest for this technology. Xerox is currently considering all potential commercialization avenues.

Q: When do you predict the erasable paper to reach the consumer market, and what obstacles do you still face in its development?

A: This is a very early research project that is several years away from reaching the market. We will be looking at a number of elements related to quality of image, length of time for the image to fade and more. There is a great deal more work to be done before this will be a product.

Q: How much do you predict the erasable paper will cost when launched?

A: Because erasable paper is still in the research centers, there is no way to speculate on what the cost of the paper will be. However, I want to clarify that this may not require a stand-alone special printer. In our prototypes, we use it as an added feature in existing Xerox multifunction devices. The erasable paper would be in one of the three or four paper drawers that these devices typically offer.

Q: What are the current limitations of the erasable paper technology? Will you be able to control the time it takes for the text to disappear?

A: Currently the image fades in about 16 to 24 hours. We do expect further research will be able to control how long the image lasts. You can also immediately erase the paper and use it again by applying a heat source or putting the paper right in the machine to be reprinted.

Q: Do you fear people will mix regular paper and erasable paper and print important documents on erasable paper? Will it be possible to allow future printers to recognize the type of paper as erasable or regular and notify the user accordingly?

A: The way Xerox multifunction devices are set up, you can currently select what type of paper you wish to use, based on sizes, color, transparencies, and so forth that are loaded into the drawers. So it will certainly be an option that you will be able to tell the printing device when to use erasable paper.

Reference Here>>

UPDATED 5-2-2008:

Xerox touts erasable paper, smart documents

The hi-tech paper can be reused up to 100 times

By Agam Shah - April 29, 2008 (IDG News Service)

Xerox Corp.'s research arm yesterday showcased its latest innovations, including erasable paper and tools that make documents "smart" by adding a deeper meaning to words and images.

Since its establishment in 1970, the Palo Alto Research Center Inc. (PARC), funded by Xerox, has created numerous technologies now available on PCs, including Ethernet, the graphical user interface (GUI) and the computer mouse. The laboratory, with other Xerox research facilities, is now trying to help its parent company and other start-ups by focusing on printing and other innovations to access, use and secure electronic documents.

Scientists demonstrated paper that can be reused after printed text automatically deletes itself from the paper's surface within 24 hours. Instead of trashing or recycling after one use, a single piece of paper can be used a second time, and reused up to 100 times, said Eric Shrader, area manager at PARC.

Predictions that paper would disappear in the 1970s in favor of electronic documents were wrong, Shrader said. As the number of electronic documents produced increases, about two to five pages are printed in the office for daily use, like e-mail messages and Web pages, which are discarded or recycled after being read. Reusable paper reduces waste, is environmentally safe, and helps reduce overall printing and paper costs, Shrader said.

Reference Here>>